plug flow reactor example problem

The next three pages will present the details and the data. The elementary liquid-phase irreversible reaction.

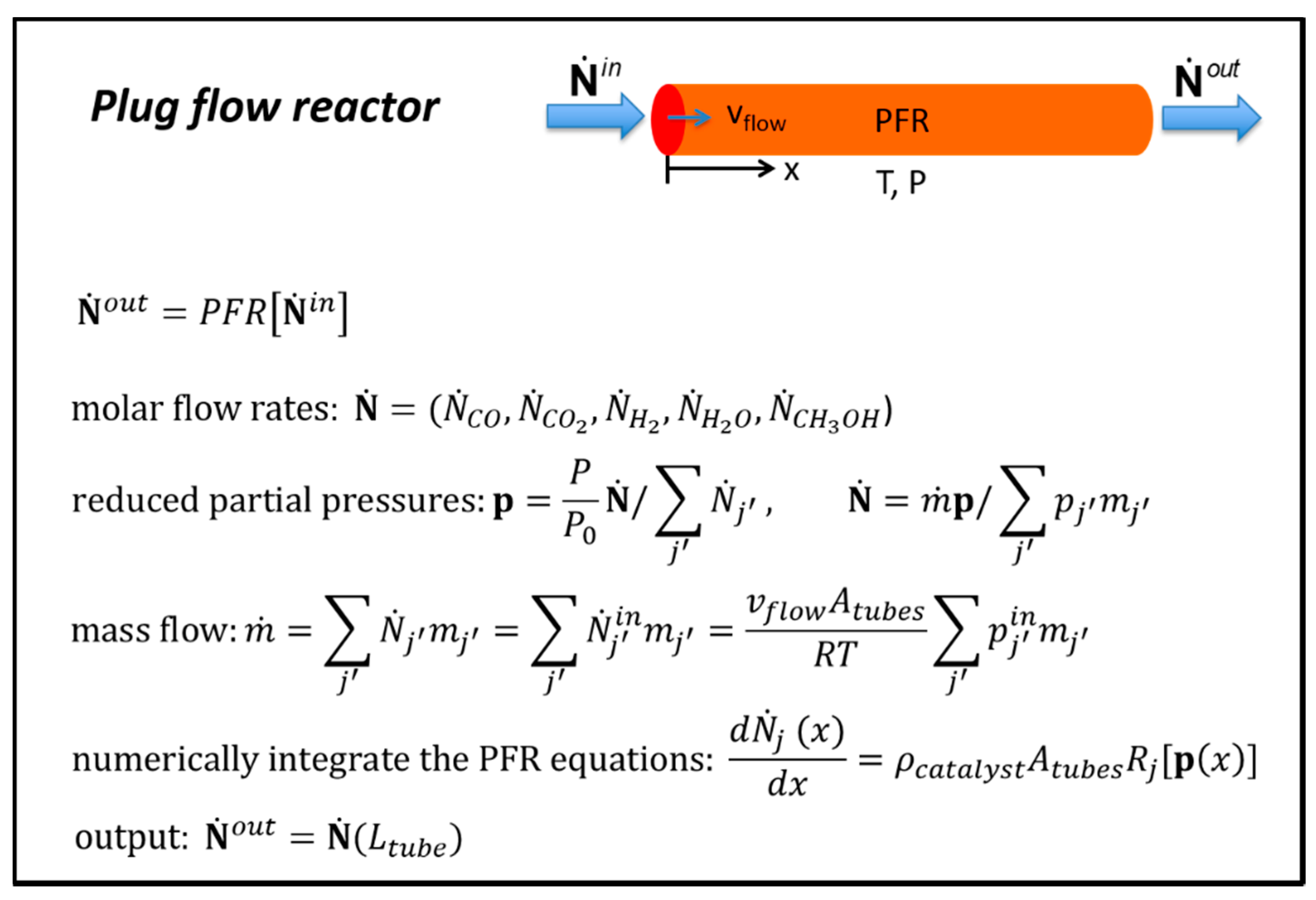

Plug Flow Reactor Pfr Mass Balance And Reaction Speed

Integrate 8 or 13 and find extent along the reactor.

. This example solves a plug flow reactor problem where the chemistry is surface chemistry. 1-11 Strategy to Solve This Problem The solution to this problem requires an analysis of multiple gas-phase reactions in a differential plug-flow tubular reactor. 9 or 14 find the heat additionremoval requirement along the reactor and the overall heat duty for the reactor.

Is to be carried out in a flow reactor. Steady-state mass balance on cells X L X o exp-k d 1k dlnX o X L 15hrln10 6103 14 hr. One production scheme involves the pyrolytic dehydrogenetation of benzene C 6 H 6 1.

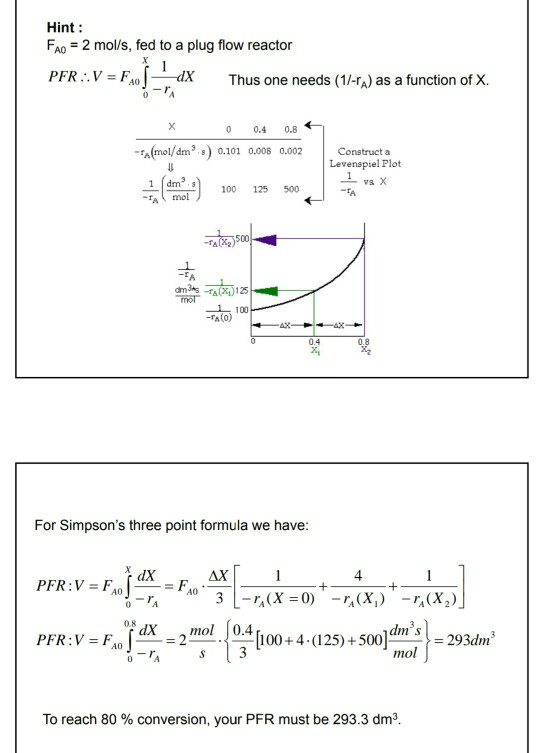

Develop equations to determine plug flow reactor size for 50 conversion of reactant A. 529 yields c0 dc c0 c 1 τ t0dt Rewritten as. Diphenyl C 12 H 10 is an important industrial intermediate.

Two different solution strategies are. Which volume is larger the PFR or the CSTR. Gas phase reaction 4A B R S is performed in a plug flow reactor.

C 2H 4 H 2 Solution Species Flow into reactor Change Leaving reactor Leaving concentration C 2H 6 A F A0 F A0X F A01 X C A C A0 1 X 1 X C 2H 4 B F B0 F A0X F A0 B X C B C A0 B X 1 X H 2 C F C0 F A0X F A0 C X C C C A0 C X 1 X The unknowns in the concentration expression. A 2B 2D r A -25C A05 C B mol L -1 min -1. One example is in the design of chemical reactors.

Example Problem - Pyrolysis of Benzene. The volumetric flow rate of the feed is 50 Lmin. Essentially no back mixing is assumed with.

Develop equations to determine plug flow reactor size for 50 conversion of reactant A. Reactor volume and flow path length L such that X L 10 3 cells100 ml 2. Two reactors are available an 800 dm 3 PFR that can only be operated at 300 K and a 200 dm 3 CSTR that can be operated at 350 K.

In order to follow this example please first import. In plug flow the velocity of the fluid is assumed to be constant across any cross-section of the pipe perpendicular to the axis of the pipe. Your answer by calculating the reactor volume in liters and the outlet molar flow rate of triethanolamine that correspond to your design.

The plug flow model assumes there is no boundary layer adjacent to the inner wall of the pipe. The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C. Taking the mass balance of the tracer in the reactor gives.

V CSTR 391 m3 c Revisit Example 1-2. Aspen Plus will be introduced with benzene pyrolysis reaction in a plug flow reactor in this tutorial. Made by faculty at the University of Colorado Boulder Department of Chemical.

The volumetric flow rate of the feed is 50 Lmin. Derive an equation relating the reactor volume to the entering and exiting concentrations of A the rate constant k and the volumetric flow rate 0. Here the Fresh Inlet is mixed with the Recycle stream.

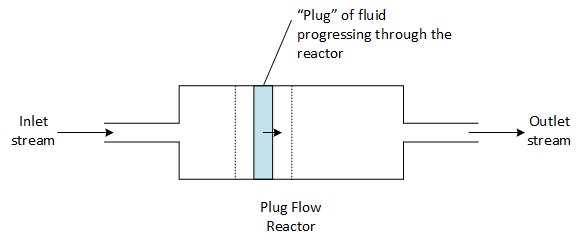

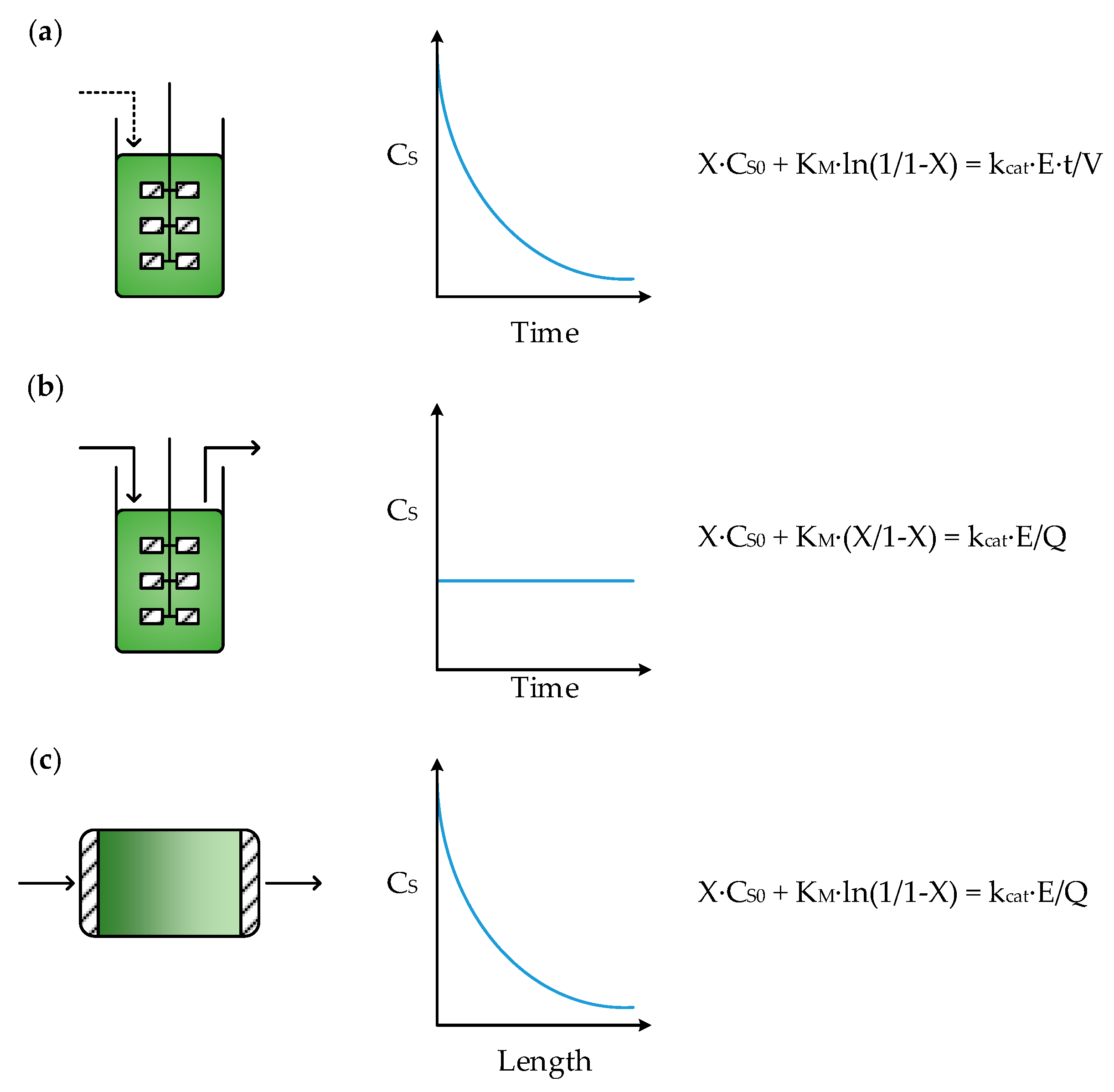

Integrate 8 or 13 find ξz. Vrdc dt Qc0 Qc Recalling Vr Q τ the above equation can be rewritten as 529dc dt 1 τc 1 τc0 This is the mathematical description of perfectly-mixed flow model. Plug Flow Reactor PFR The third general type of reactor is the Plug Flow Reactor PFR.

A brief overview of plug flow reactors their properties equations and uses. The temperature in the reactor is prescribed a. 1Set up the table for a flow reactor at 6 atm and 1110K for the reaction.

Suggest two ways to work this problem incorrectly. Tz T o isothermal reactor. Formation rate of R is empirically correlated by the equation B A A B R C C C C r 1 05 1 rR in molLh CA and CB in molL The plug flow reactor is fed with a flow rate of 200 kmol A h and the feeding is 50 A and 50 B.

In the case of tube flow the accepted ideal is the plug-flow reactor in which it is assumed that there is no mixing in the axial flow direction but perfect mixing in the directions transverse to this. Chlorine concentration which must be added to insure that there is detectable chlorine at PFR exit detection level C L 005 mgL 1. Calculate the volume of a CSTR for the conditions used to calculate the plug-flow reactor volume in Example 1-2.

The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C. Calculate the time to reduce the number of moles of A to 1 of its initial. The specific problem simulated is the partial oxidation of methane over a platinum catalyst in a packed bed reactor.

Stream goes to a separation process from which the Recycle stream is returned to the inlet and the final system outlet is stream Both Estimation and Optimization modes are considered next. The resulting stream enters the PFR reactor and stream is the reactor effluent. Thoughts on Problem Solving.

Determine the reactor volume V necessary to reduce the exiting concentra- tion to 10 of the entering concentration ie CA 01Cao when the volumet- ric flow rate 2 is 10 dmmin ie litersmin and the specific reaction rate k. The plug flow model has many practical applications. Basic types of problems 1.

It can be shown2 that the absence of axial mixing allows the achievable reactant conversion to be maximized. The reaction takes place at 3 atm and 150C. In a plug flow reactor nutrients and sometimes organisms are introduced to the reactor continuously and move through the reactor as a plug.

The two feed streams to the reactor mix to form a single fee d stream that is equal molar in A and. The system may be either contained as in a water main oil pipeline or blood vessel or open as in a. The initial condition is t 0 c 0 Integrating Eq.

One Dimensional Pseudo Homogeneous Plug Flow Reactor Model Download Scientific Diagram

Solved Example Consider The Liquid Phase Reaction A Chegg Com

Summary Of Mixing And Flow Regimes In Flow Reactors A Radial Versus Download Scientific Diagram

A Front View Of The Plug Flow Reactor And B Surface Area Dimensions Download Scientific Diagram

Catalysts Free Full Text Reactor Selection For Effective Continuous Biocatalytic Production Of Pharmaceuticals Html

1 4 Continuous Flow Reactors Mole Balances In Chemical Reaction Engineering Informit

Consider The Following System Differential Equation Chegg Com

Isothermal Plug Flow Reactor Part 1 Youtube

Matlab In Chemical Engineering At Cmu

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

Plug Flow Reactor Model A Plug Flow Reactor Pfr Model Is Used By Justin Mitchell Medium

An Inclined Plug Flow Reactor Design For Supercritical Water Oxidation Sciencedirect

Plug Flow Reactor An Overview Sciencedirect Topics

Thoughts On Problem Solving Pfr Cstr Example

Mole Balance On A Plug Flow Reactor Youtube

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram

Chemengineering Free Full Text Understanding Catalysis A Simplified Simulation Of Catalytic Reactors For Co2 Reduction Html